MachineSafe is a purpose build machinery safety software platform designed and optimised for machinery safety and compliance audits. Whilst there are various checklist apps available on the web, MachineSafe has been designed by experienced machinery safety engineers to allow for detailed inspections and audits, but without the burden normally associated with such activities.

MachineSafe comes with a number of inspection modules included in the Enterprise subscription, plus users have the ability to add their own inspections in to MachineSafe, such as food safety or a inhouse PUWER inspection.

Company multi-user comes as standard which allows for colleagues to benefit from MachineSafe at no extra cost.

Our inspection modules cover the complete asset life cycles, from new machinery compliance audits, electrical (60204-1), pneumatic and hydraulic, risk assessment, safety audits and PUWER. A CE/UKCA Plugin is also available with allows machinery users to carry out conformity assessments should they carryout a significant modification to their assets.

Reports can be generated at any point during the inspection for distribution to stakeholders.

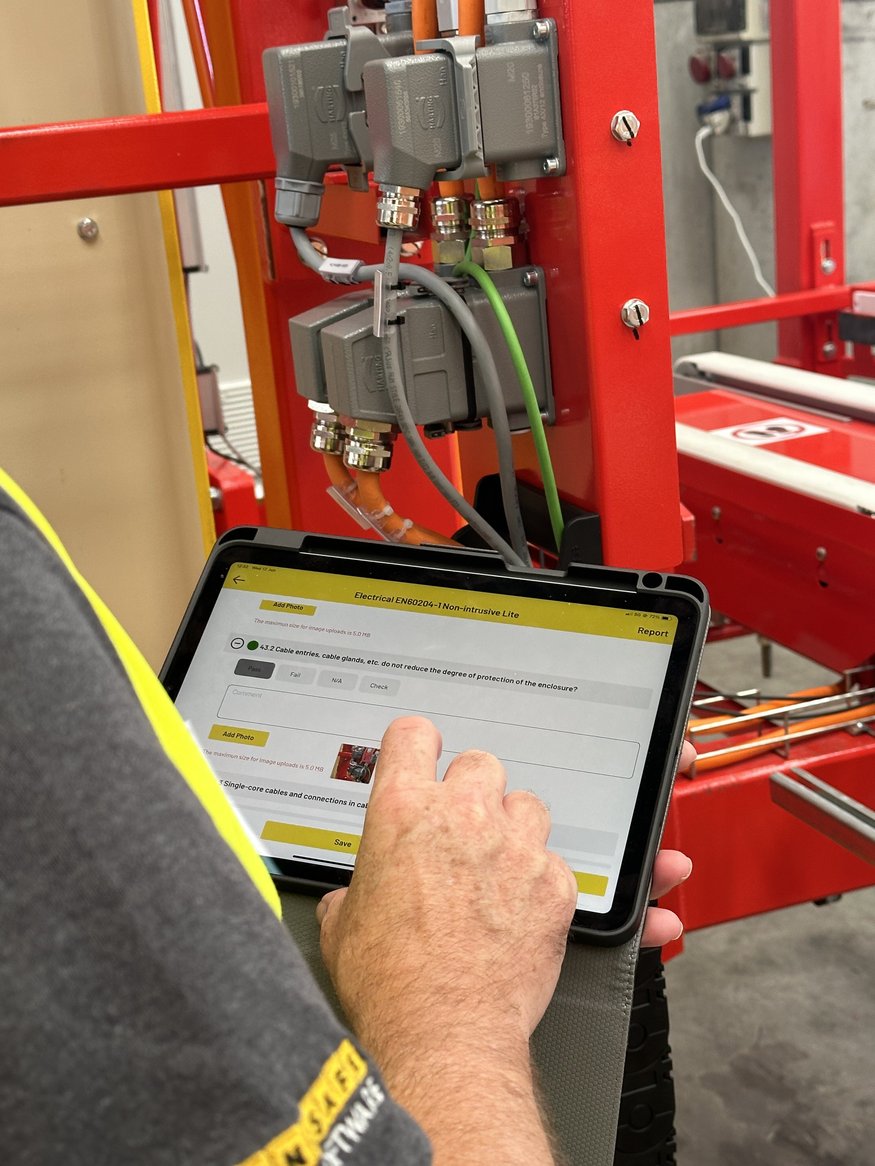

During a recent Factory Acceptance Test (FAT) in Italy, a MachineSafe consultant customer, Safemach used the MachineSafe app. to carryout various inspections and audits on the new machinery to ensure it was compliant prior to shipping to the UK based customer.

Inspections were carried out using the EN 60204-1 Electrical Inspection and the New Machinery Compliance Audit modules. Machinery end-users often assume that new machinery will be compliant because it is CE or UKCA Marked, however this is not always the case. Using the MachineSafe modules for new machinery allow for structured and detailed inspections to be carried out during supplier visits such as an FAT. Following the inspection, reports can be generated and distributed to stakeholders and the supplier, allowing for non-compliance topics to be addressed prior to shipment. When machinery is sent to the end-user without first carrying out a new machinery compliance audit, issues can take a long time to rectify.

A multitude of non-compliances are often seen during new machinery compliance audits with common issues being poor machinery documentation including O&M Manuals, BOM, statutory testing, Sistema (13849-1) and electrical drawings, access to dangerous parts of machinery, missing warnings and marking.

If you are have or are planning to purchase new machinery, then please contact MachineSafe to see how are machinery safety and compliance software platform can assist in ensuring your new machinery is compliant and safe.